Towards commercial solar thermochemical production of sustainable drop-in fuels

Funding source: Center for Sustainable Future Mobility

Partners: external page Synhelion, external page AMAG, external page SBB, Professorship of Climate Policy

Postdoc: Dr. Vikas Patil

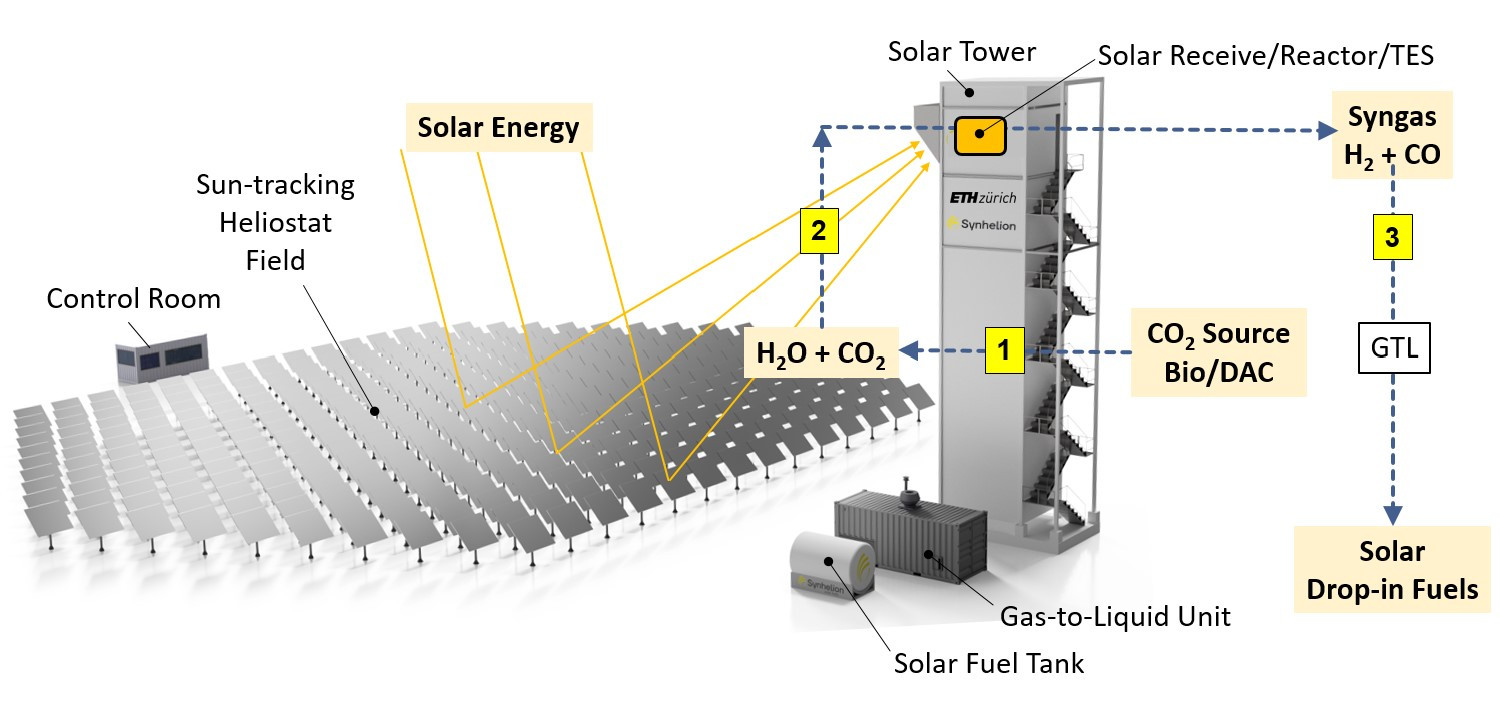

Project abstract – The production of sustainable drop-in fuels for the transportation sector – synthetic and completely interchangeable substitutes for conventional petroleum-derived hydrocarbons (e.g. gasoline, diesel, kerosene, methanol) – can be realized with the help of technologies that convert H2O and CO2 into fuels using solar energy. Developing scalable and economic viable solar fuel technologies has become a global energy challenge, but their technology readiness level (TRL) has largely been limited to benchtop laboratory studies. To address this challenging problem, ETH researchers have developed the science and technology for solar fuels production and have recently demonstrated the entire process chain to solar fuels at the pilot scale. To further advanced the development, we propose in this project to perform a comprehensive techno-economic feasibility study of the industrial-scale production of drop-in transportation fuels using concentrated solar energy. The generic solar fuel plant comprises the solar concentrating system, the solar receiver, the thermal energy storage unit, the thermochemical reactor, and the gas-to-liquid synthesis unit. Crucial to this study is a thorough examination of the performance of the technologies involved and their scalability, including the analysis of the mass/energy flows, efficiencies, and system integration. The technical evaluation will be complemented by an economic and environmental assessment of the entire process chain, with focus on the solar production in south Europe and delivery of drop-in fuels to the Swiss market. This project will further elucidate the R&D efforts and public policies required for the commercial implementation of solar fuel production plants and for accelerating the transition from fossil to solar fuels.

Project-related Publications