CCEM Project - Solar Ceria Redox Cycle

Project website: external page http://www.ccem.ch/solar-fuels

Funding source: external page CCEM - Competence Center Energy and Mobility

Partners: external page EMPA, external page PSI

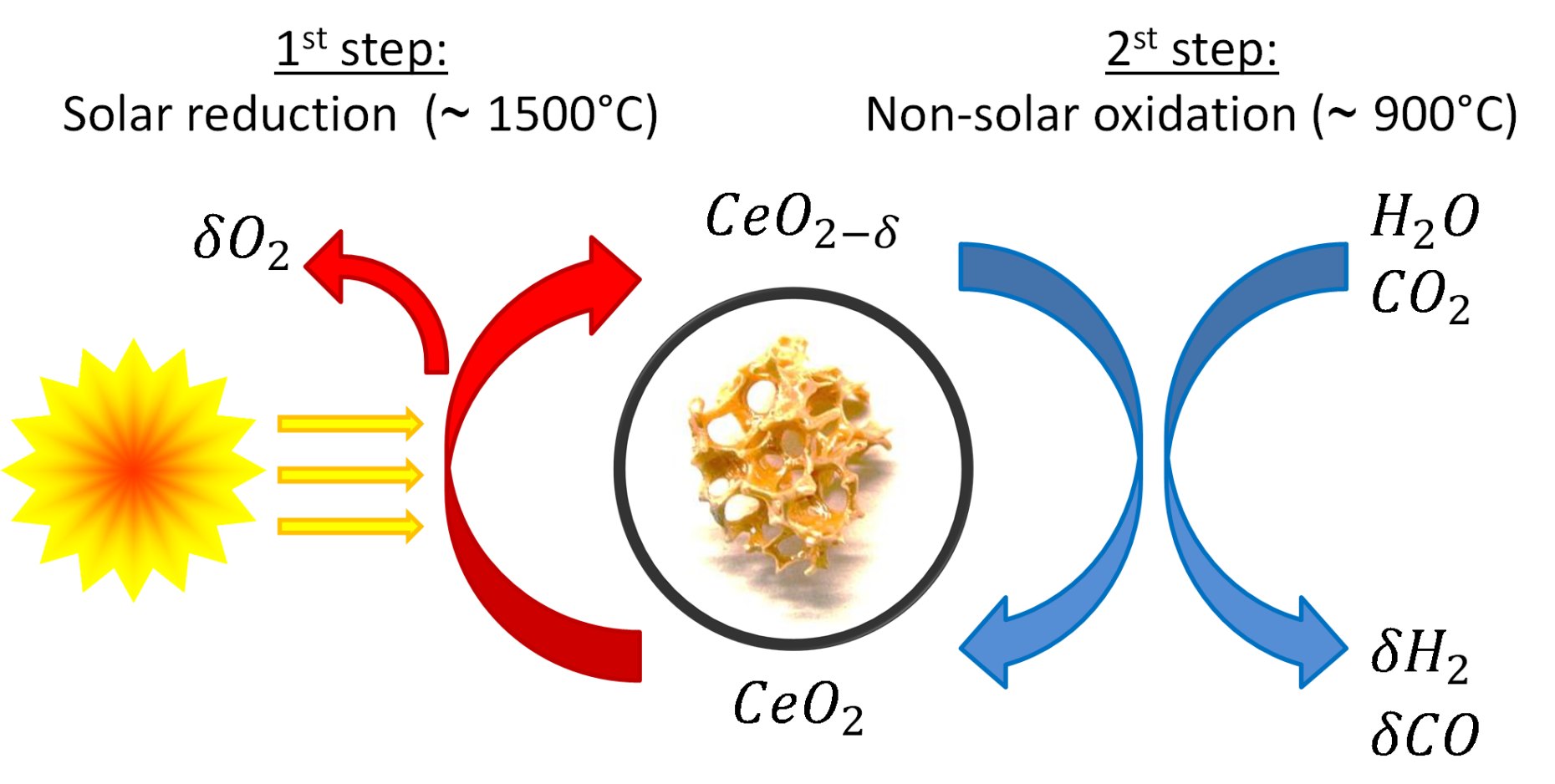

Background – Concentrated solar energy is used as the source of high-temperature process heat to split H2O and CO2 via a 2-step thermochemical redox cycle. The first, endothermic step is the solar thermal reduction of the metal oxide.

The second exothermic step is the oxidation of the reduced metal oxide with H2O and CO2 to form H2 and CO (syngas), and reform the original metal oxide which is recycled to the first step. Syngas is the building block for a wide variety of synthetic fuels. Ceria is a promising redox material for this cycle.

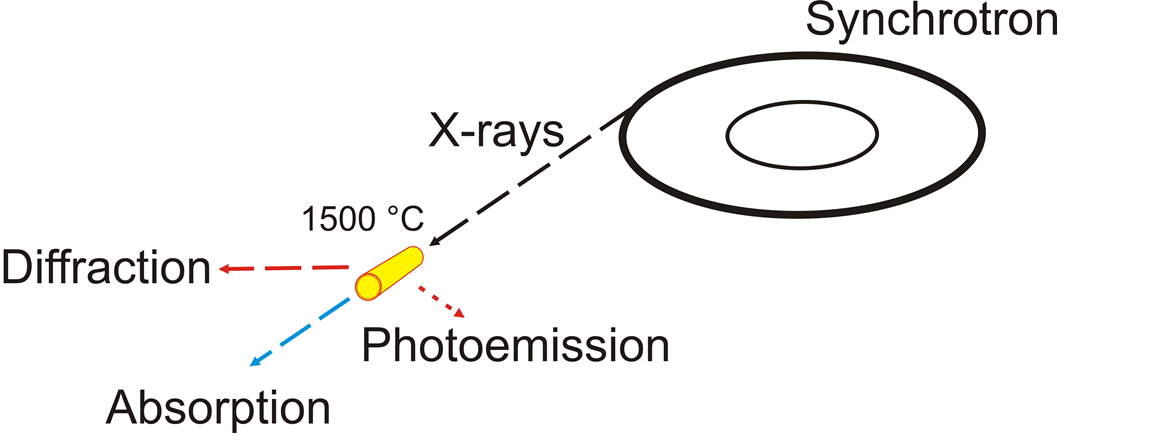

Synthesis and in situ characterization of redox materials – Novel redox materials are prepared via different synthesis routes and are characterized in situ. Synchrotron-based techniques allow the determination of the electronic structure and activity, which in turn enable to establish relationships between performance and structure.

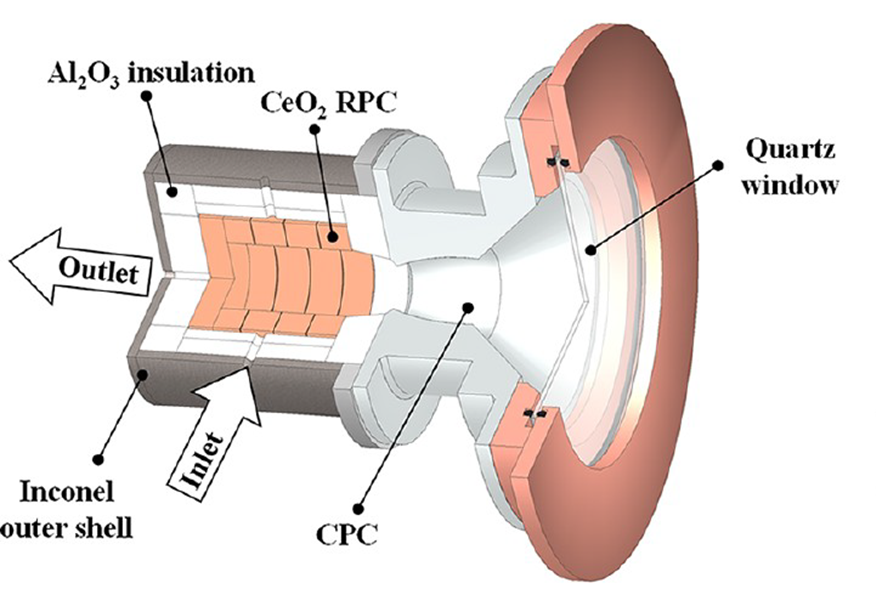

Fabrication and engineering of reticulated porous ceramics (RPC) – The RPC structures are produced by the so-called Schwartzwalder method. The final structure exhibits high macro-porosity and acts as an efficient solar absorber, Optimum porosity and chemical composition of the RPC is studied with various microstructural analysis methods.

Determination of effective heat and mass transfer properties – The exact 3-D geometry of the RPC is obtained by computed tomography. The effective heat and mass transport properties are determined via direct pore-level simulations of the governing momentum and energy conservation equations.

Project-related Publications