EU-Project TCSPower – Thermochemical Energy Storage for CSP Plants

Project website: external page www.tcs-power.eu

Funding source: external page European Union

Partner: external page Deutsches Zentrum fuer Luft- und Raumfahrt e.V. (Germany), external page Siemens Concentrated Solar Power LTD (Israel), external page Bühler AG (Switzerland), external page Eramet & Comilog Chemicals SA (Belgium), external page Fundacion IMDEA Energia (Spain), external page Paul Scherrer Institut (Switzerland), external page Universitaet Siegen (Germany)

Background – Intermittence of renewable power supply and high power generating costs are the major technical and economical obstacles to widespread commercial use of regenerative energy sources. In contrast to photovoltaic or wind power, concentrated solar power (CSP) has the potential to provide dispatchable power on a defined capacity level by integrating large-scale thermal energy storage. Efficient, reliable and economic thermal energy storage technologies will thus improve economics and raise the market potential of CSP technology.

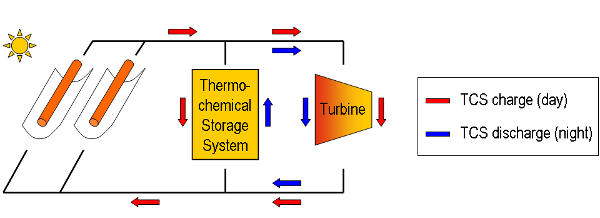

The overall objective of the TCSPower project is to realise a new, efficient, reliable and economic thermochemical energy storage (TCS) for concentrated solar power plants which has the capability to contribute significantly to further cost reduction of regenerative electricity production. This will be achieved by applying reversible gas-solid reactions. Dissociation of calcium hydroxide is used for storing thermal energy in a temperature range between 450 and 550°C in connection with trough power plants with direct steam generation. For the higher temperatures of central air receiver CSP plants the redox reaction of manganese oxide will be applied.

The reversible endothermic/exothermic reactions considered are:

Ca(OH)2 ↔ CaO + H2O

6 Mn2O3 ↔ 4 Mn3O4 + O2

Objectives – The project is aimed at the evaluation of both concepts in laboratory scale. Based on the obtained results, an up-scaling to 10kW will be realized for the more promising reaction system to evaluate the performance of a pilot-scale TCS reactor experimentally. Finally, strategies for up-scaling to commercial scale and a techno-economic evaluation of the thermochemical storage systems will be developed. PSI’s major contribution lies in the development of a simulation tool for the design of TCS reactors with improved heat and mass transfer characteristics to be applied for non-catalytic reversible gas-solid reactions. It involves the following tasks:

- Development of a heat and mass transfer model coupled to the reaction kinetics.

- Investigation of the influence of storage material properties, storage device geometry and operating conditions.

- Validation of the numerical model with experimental results.

Project-related Publications